In modern times, MOM is serving as a savior of sorts. A well-defined approach of integrating several technologies and strategies into a harmonious package that works to optimize production processes, increase efficiency, and vastly improve overall business performance. Over the years, manufacturing software solutions in the market have helped boost the efficiency and productivity of your business and can raise several bars.

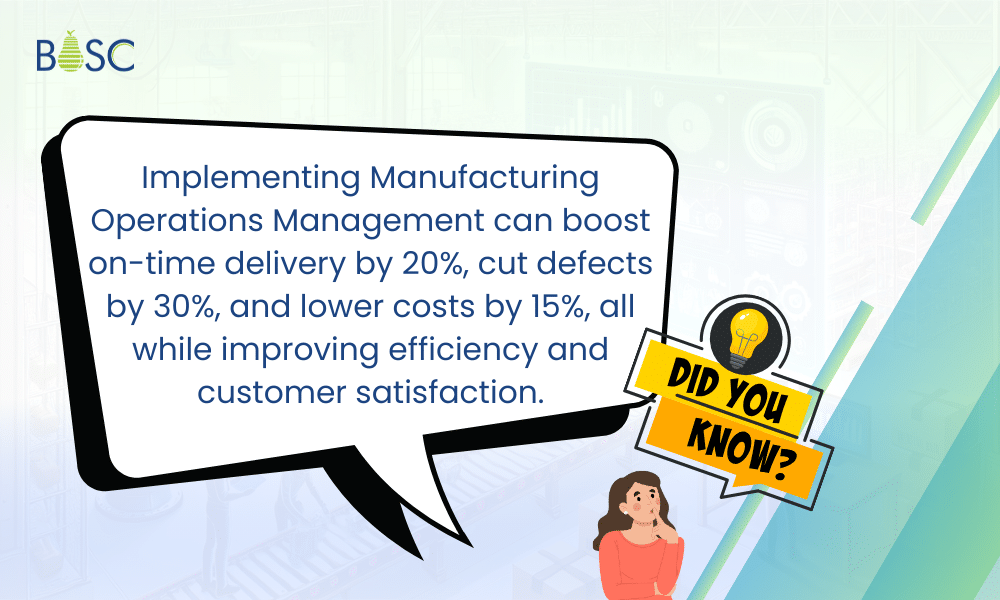

Manufacturers today are constantly pressed for the best products within time constraints, and without this affecting costs in an otherwise global-market scenario. They will need to understand that a good grasp of MOM software will become the requirement for calibration with their production peaks and to maintain competitiveness. With Manufacturers Operations Management solutions in place and competent technologies applied, have a pavement opened to enormous capabilities with resulting improvement in customer satisfaction and innovation.

If you too are looking for an MOM solution to help you in managing your workflow, partnering with a dedicated app development company can help.

What is Manufacturing Operations Management (MOM)?

Manufacturing Operations Management (MOM) take a more holistic approach to managing and optimizing production processes. In other words, MOM embraces and relates as many activities as planning and scheduling, execution, monitoring, and optimization. With this integrated approach, a well designed MOM unleashes technologies and strategies that allow manufacturers to become more profitable, improve product quality, and reduce costs.

With technology advancing, Manufacturing Operations Management Software can help you automate the processes and update you with the transformations in your business. Let’s understand how does manufacturing solution function.

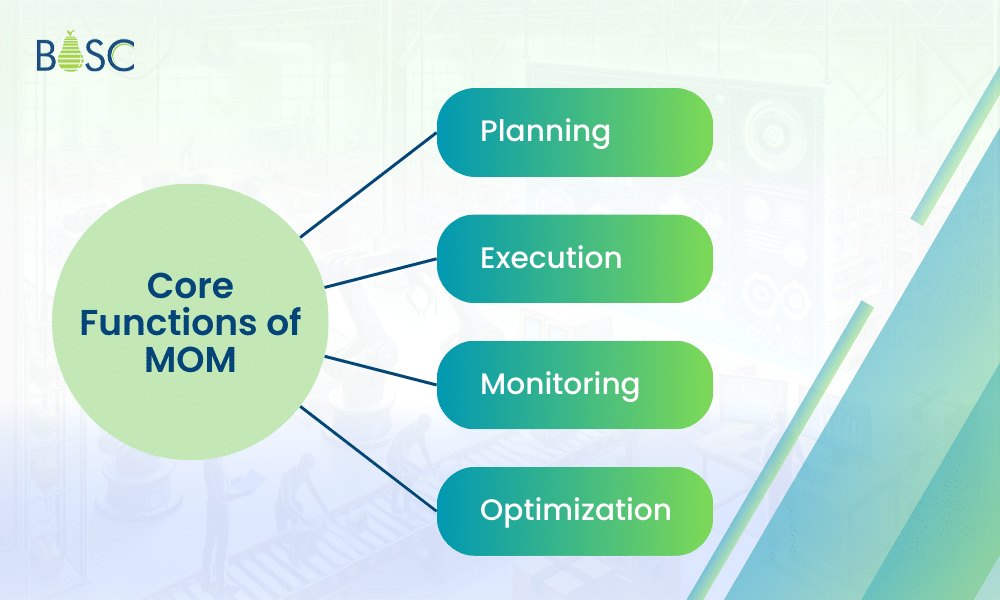

MOM Software Involves Four Core Functions

- Planning: The software involves preparing an effective and detailed production plan, task scheduling, and resource allocation to enable optimum utilization to be put in place.

- Execution: The efficient execution of the developed plan, which includes work order management, job scheduling, and real-time tracking.

- Monitoring: MOM allows visibility into production in real-time so that key performance indicator (KPI) evaluation can be done to predict and identify impending problems.

- Optimization: While MOM leverages the data being collected off the production floor so that managers can investigate improvement opportunities, this could mean rescheduling operations, tweaking processes, or adopting new technologies.

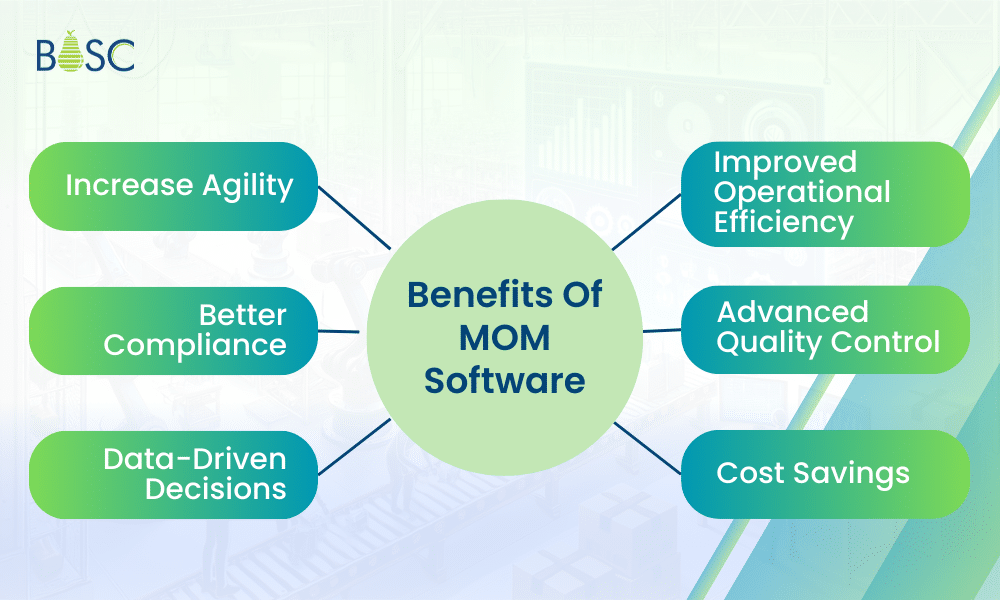

Benefits of Implementing MOM Software

Manufacturing Operations Management solutions provide a wide range of possible benefits that would, to a considerable extent, improve the performance of a manufacturing organization. MOM software allows manufacturers to sustain competitiveness in the changing market of the contemporary world through process optimization, higher quality, and lower costs.

Improved Operational Efficiency

Minimization of Downtime

Whenever failures do arise from the machines, virtually MOM systems eliminate waiting and offer predictive functions for active addressing of events that could lead towards such failures, thus minimizing equipment downtime to maximize production time.

Optimized Production Scheduling

Optimized production schedules are prepared that can balance workloads and resource utilization through aggregation of real-time data with historical data.

Streamlining Workflows

Other advantages include automating repetitive tasks, identifying and removing bottlenecks resulting in well-organized workflows and shorter cycle times.

Enhanced Productivity

Moreover, MOM improves productivity by optimizing resources and streamlining processes, ensuring better outcomes with less effort.

Advanced Quality Control

Real-time Monitoring

The users of MOM would get to know what is happening during the entire production in real-time, thus enabling timely corrective action for better quality by identifying and treating any quality issues as soon as they arise.

Enhanced Product Quality

Depending on analyzing product defects and process variation, it will open ways whereby MOM users would highlight the root causes and initiate remedial handling so as to overcome similar problems in the future.

Improved Traceability

MOM will, at the same time, enable enhanced traceability of products so that manufacturing companies can quickly identify and isolate defective products.

Less Rework and Scrap

Reduced rework and waste possibilities will indeed provide great cost-efficiency. Thanks to MOM.

Cost Savings

Lowering Labor Costs

In general, MO attempts to keep labor costs down while also combining various strategic operating methods.

Lowering Inventory Cost

Carried in the inventory of goods, reduced time will mean in the long run less inventory-carrying cost.

Lower Energy Consumption

MOM software would also give a number of opportunities in the matter of energy savings through machine-parameter optimization by producing during off-peak rates.

Lower Maintenance-Related Costs

Predictive maintenance and other functions offered through the employee capabilities of MOM solutions prevent equipment breakdowns and reduce maintenance costs as well as unplanned downtimes on all production runs.

Increase Agility

Faster Products

MOM systems can accelerate product development and commercialization by speeding up the design, engineering, and manufacturing processes.

Quickly Respond to Market Changes

MOM software lets manufacturers quickly adapt to fast-changing market demand patterns and consumer preferences.

Flexible Capabilities of Production

MOM solution is able to exchange production plans as needed with seamless transition capabilities.

Better Compliance

Regulatory Compliance

The aid to MCP in complying with the industry regulations and standards in relationship to health and environment can be catered for-MOM.

Improved Documentation

Documenting may be undertaken by a comprehensive MOM system to ensure that documents are accurate and timely.

Audit Preparedness

MOM software can help establish a more amenable environment for conducting audits and inspections, by keeping detailed electronic rolls and reports.

Data-Driven Decisions

Making the Right Choices Based on Data-MOM has stacked several whacks of resources to the cube and the timber for decision-makers to resort to when turning a multitude of valuable insights into action.

- Continuously Improving: This is an initiative for ongoing improvement of producers where manufacturers analyze their performance data in quest of problematic areas for potential improvement.

- Minimizing Risks: MOM, being able to anticipate risk, can thus act to minimize the occurrence of problems before they actually happen and take steps to mitigate the situation.

How MOM Works?

Manufacturing Operations Management software gathers real-time data from various sources to keep track of production processes. This data is then analyzed for trends, possible issues, and eventual decisions. The resulting observations enable manufacturers to automate tasks, amend schedules, and optimize resource allocation.

Key Steps Involved

- Data Collection: The data is collected from various data sources like sensors, machines, and ERP systems.

- Data Analysis: Analyze the data and monitor the progress.

- Decision-Making and Adjustments: Manufacturers with the ability to resort to algorithmic routines for the automated decision-making of scheduling and adjustment of machine parameters.

MOM software has worked well over the years and businesses looks for such integrations to automate and manage their businesses. If you are looking for a white label MOM solution to manage your business, BOSC Tech Labs is the place for you.

The Future of MOM and Its Impact on Businesses

Emerging Technologies

Artificial Intelligence

Artificial Intelligence has changed the very framework and process of management of manufacturing. Cognitive decision making, predictive analysis, and process automation are in the hands of AI-Machine-learning algorithms can analyze enormous amounts of data and find patterns that will ultimately optimize failures in operations.

Internet of Things

Manufacturers are now capable of real-time monitoring and control of their production processes due to the interconnection of machines, sensors, and other equipment through IoT devices. The data collected through these devices helps manufacturers optimize performance, reduce downtime, and improve quality.

Predictive Analysis

Predictive Analysis aims to project the future based on past records using advanced algorithms in order to enable effective proactive action to stay ahead of the competition. This technology would predict possible machinery failures, optimal inventory, and possible future demand fluctuations.

Initiative for Sustainability

Sustainable Manufacturing

Diverse areas of manufacturing are being done by MOM-Sustainable based. So far, they work towards reducing energy consumption as well as minimizing waste and optimizing the consumption of other resources.

Circular Economy

Thereby using this integrated concept of the principles of a circular economy within their operational tasks, producers manage to limit their waste generation, conserve resources, and contribute towards the creation of a greener world.

Reduction of Carbon Footprint

MOM manages to assist manufacturers in tracing and reducing their carbon footprints towards increased energy efficiency, waste reduction, and enhanced supply chain efficiencies.

Global Adoption of MOM

Industry 4.0

The trends these days toward stepping up MOM adoption, other facets of Industry 4.0 are speeding up the digital revolution mainly in the manufacturing sector globally.

Emerging Markets

While these economies, namely China and India, speedily develop with MOM, there is a jump in manufacturing capacity that helps in leveling up with counterparts globally.

Cross-Border Collaboration

Remote work raised the sentiment and desire, through MOM, to share knowledge, best practices, and climate technology, creating a new point of synthesis between the entire world beyond normal borders. MOM is making it easy for these collaborations by enabling the very important exchange of data and remote hostile interaction.

In Summary

Emerging as a potential tool for operational excellence within the manufacturing arena, Manufacturing Operations Management integrates technology, data analysis, and best practices to streamline processes, assure product quality, and contain costs.

Modern-day competitiveness demands that MOM software be integrated for organizational survival since manufacturing is in a state of constant change. At www.bosctechlabs.com, we have well developed MOM systems that will give manufacturers a chance to add real value and provide a high level of customer satisfaction and success in the future.

Partner with Us for MOM Solutions!

Collaborate with us to boost manufacturing efficiency and quality.

Get Started Today!