In the modern manufacturing world, efficiency is everything. As companies seek to enhance their production capacity, cut on costs, and produce high quality products, equipment reliability is of paramount importance.

However, many manufacturers have not been able to avoid cases of machinery breakdowns that disrupt production lines, increase maintenance expenses, and compromise customer confidence. The traditional approach to maintenance is inadequate in the modern world, where organizations are producing large amounts of data at a very high rate.

This is where predictive maintenance comes into the picture. Thanks to IoT sensors, AI, and machine learning, problems can be foreseen before they happen in the production line. Get the best manufacturing software development services from BOSC Tech Labs to implement cutting-edge predictive maintenance solutions and ensure seamless production.

It is not just about repairing equipment – it is about redefining the process, reducing downtime, and optimizing production in ways that have never been seen before. The predictive maintenance market size was $9.8 billion in 2024 and is expected to reach $88.8 billion by 2032 at a CAGR of 31.6%.

What is Predictive Maintenance?

Predictive maintenance (PdM) is an intelligent maintenance technique that uses current data, sensors, and artificial intelligence to anticipate equipment failures. PdM differs from other approaches that require responding to failures or carrying out maintenance at predetermined intervals.

Some of the examples of the variables that are measured include vibration, temperature, pressure, and energy consumption. The system then processes this data in order to identify any signs of wear, misalignment or other problems. These insights assist in planning for maintenance to be done at the appropriate times—in order to prevent failure.

This approach helps to reduce the time during which equipment is out of service for maintenance, avoid frequent maintenance, and lengthen equipment’s service time. It helps in effective and efficient operation of machines and at the same time reducing the cost of operation. Predictive maintenance is progressively becoming a vital tool in today’s smart manufacturing industries. If you’re exploring how vision-based AI plays a role in this transformation, check out our article on how computer vision powers AI-driven process optimization in manufacturing.

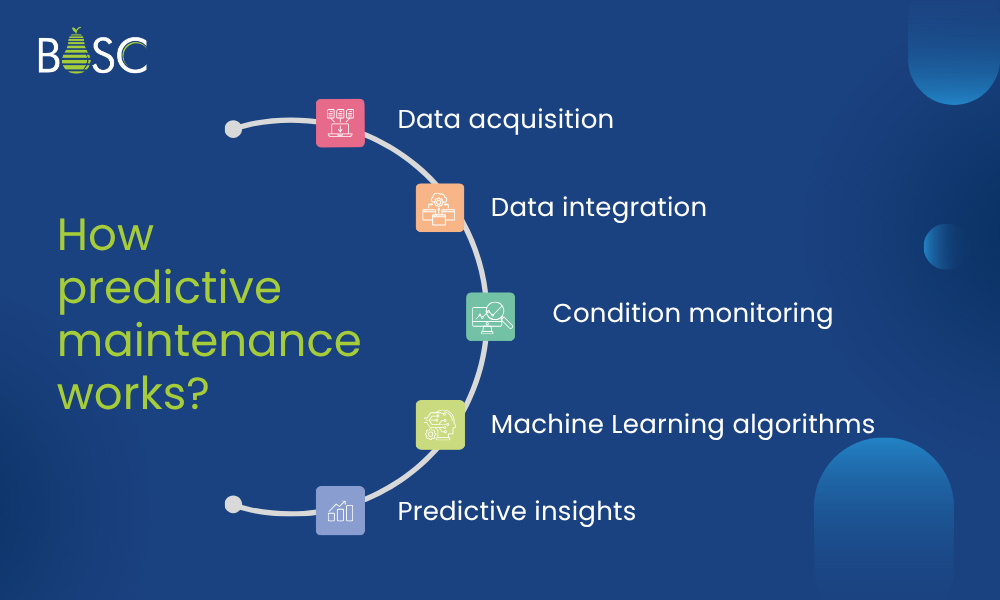

How Predictive Maintenance Works?

Data Acquisition

Measuring devices are placed on the machinery to monitor various parameters during its operation such as temperature, vibration, pressure, and speed. These sensors are used to monitor equipment health and therefore generate real-time data. This data forms the basis of when a particular component will likely fail or will require some attention.

Data Integration

The collected sensor data is then fed to centralized systems such as ERP, MES or CMMS systems. This step enables the manufacturers to integrate the performance data of the machines, its maintenance records, production calendar, and other contextual information, which gives a holistic view of the health and performance of the asset in a given time frame.

Condition Monitoring

After data is acquired and incorporated into the system, it is constantly checked against normal operating levels. Any deviation, for example, in vibration or temperature is detected immediately. It is useful in identifying signs of degradation or failure of the equipment before it becomes worse.

Machine Learning Algorithms

The monitored data is then analyzed by the more sophisticated machine learning models to detect patterns associated with failures. These algorithms get better with time and are more refined given the increasing number of data they process. They can distinguish between variations that are normal and those which are dangerous, thus avoiding false alarms.

Predictive Insights

From the algorithms, the system is able to predict when a particular item requires maintenance. These insights are then provided to the maintenance teams through dashboards or alerts to allow for timely actions to be taken. This approach helps to eliminate unnecessary downtimes and perform maintenance only when necessary—saving time, money and resources.

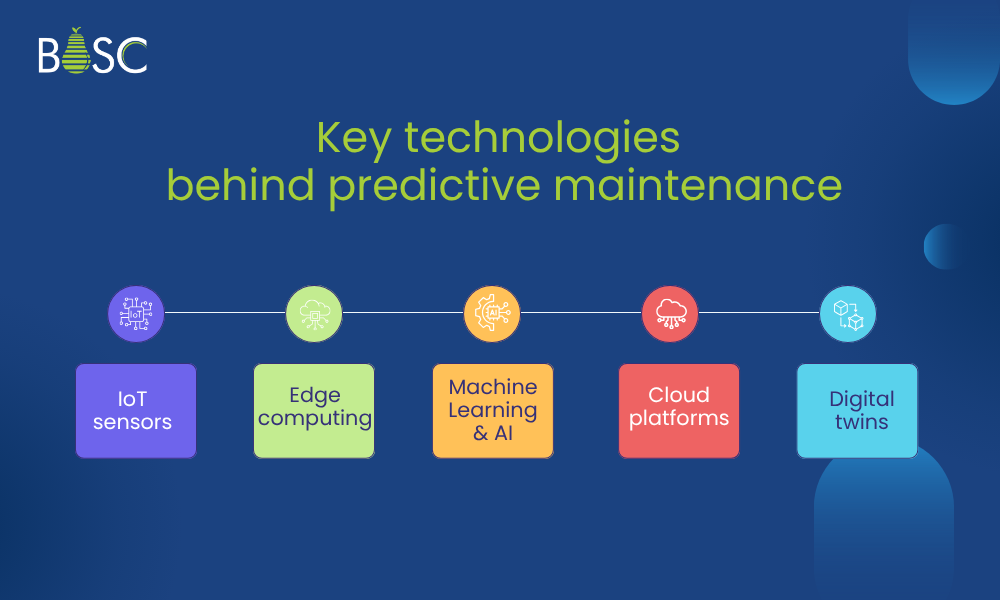

Key Technologies behind Predictive Maintenance

IoT Sensors

IoT sensors capture real-time data from the machines in terms of temperature, vibration, pressure, and noise, among others. This continuous monitoring helps in determining the signs of wear or malfunction early before they cause a significant impact on the performance of the vehicle. These are the most crucial elements of any predictive maintenance system.

Edge Computing

Edge computing is a computing system where data is analyzed near the source of the data, that is, on the device or machine. This helps to minimize time and hence promotes quick decision making. In predictive maintenance, edge computing helps in the identification and resolution of any problems with the machines as soon as they occur.

Machine Learning & AI

The algorithms used in the development of this model identify factors that are likely to occur before equipment failure based on historical and real-time data. The models improve with time and provide reliable forecasts as well as suggesting corrective measures to be taken in order to avoid major failures.

Cloud Platforms

Cloud computing offers the required infrastructure to store and process large volumes of data generated by machines. It also allows for the monitoring of dashboards and KPIs from a distance, which is beneficial for maintenance teams and decision-makers who manage assets at multiple sites.

Digital Twins

Digital twins are replicas of physical systems that are used to mimic operational conditions and performance. In this way, with the help of real machine data and digital twins, the predictive systems can find out when and where the failure occurs and can take necessary actions in advance.

Benefits of Predictive Maintenance in Manufacturing

Predictive maintenance can reduce the maintenance costs by 12%, increase the availability of equipment by 9% and increase the lifespan of the aging equipment by 20%. Here are some more benefits:

Reduced Downtime

Preventive maintenance enables one to plan for equipment failure before it happens. As a result of this, manufacturers can prevent breakdowns, reduce the time lost due to breakdowns, and keep production running smoothly. This greatly minimizes time lost due to equipment failure and enhances the use of the equipment as well as general productivity.

Lower Maintenance Costs

In PdM, the maintenance is done only when necessary, thus avoiding unnecessary replacement of parts and manpower. It avoids over servicing as well as emergency repairs, both of which are costly. In the long run, this approach reduces the overall cost of maintenance while not affecting the reliability and efficiency of the equipment.

Extended Asset Lifespan

Equipment health check and addressing signs of wear and tear helps avoid worst-case scenarios of their deterioration. This makes it possible for machines to run for a longer time before they will require a major overhauling or replacement. Consequently, manufacturers obtain higher value from their capital investments and do not experience early asset turnover.

Data-Driven Decision Making

PdM systems produce a large amount of data and information regarding the health and performance of the equipment. This helps managers to make better decisions regarding their scheduling, budgeting, inventory, and workforce, thus enhancing the strategic planning and coordination of maintenance with production objectives.

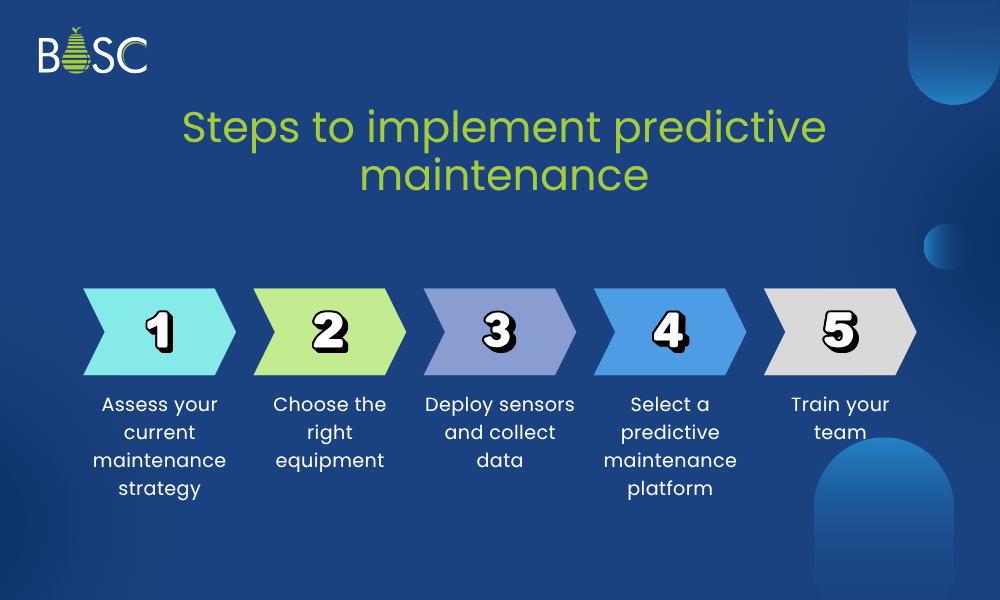

Steps to Implement Predictive Maintenance

Assess your Current Maintenance Strategy

Begin by assessing how maintenance is done in your facility at the moment. Determine which assets fail more often, where the downtime is most expensive, and what solutions exist at the moment. It assists you in defining objectives and scope, which in turn help you identify where to start.

Choose the Right Equipment

Not all machines require to be put on a predictive maintenance schedule at the onset. A targeted approach guarantees early achievements and tangible ROI on your PdM initiatives.

Deploy Sensors and Collect Data

It is recommended to install IoT sensors to track the critical parameters of a machine, such as temperature, vibration, and power consumption. These are the data inputs into your predictive system. Use a limited number of machines initially to check data flow, performance and system response before going large scale across the plant.

Select a Predictive Maintenance Platform

Select a software platform that will be able to receive and process data from the sensors, use machine learning, and generate alerts. To be effective, it should be compatible with your current ERP, MES or CMMS systems. Seek a solution that is easily expandable and is built on the cloud to suit future operations and analytics.

Train Your Team

Your staff has to be aware of how the platform works, how to read the alerts, and what decisions to make. Offer practical experience and follow-up guidance. It is important for the maintenance technicians, operators and managers to know how the predictive maintenance process integrates with the day-to-day operations and the strategic planning.

Partner with Experts

Successful implementation often requires outside help. Consult with professionals who have expertise in the field of predictive analytics and manufacturing software. For long-term success and tailored solutions, rely on experienced developers who can customize tools to meet your unique needs and drive continuous improvement in your production processes.

Conclusion

Predictive maintenance is not just a concept that will save money, but it is a strategy that will revolutionize the manufacturing industry. This makes it possible for companies to move from the traditional methods where maintenance is done based on time or based on a schedule to a new approach that is based on the condition of the equipment. It not only minimizes the amount of time that equipment undergoes unscheduled maintenance but also increases the overall durability and reliability of the assets and the process.

If you want to develop predictive maintenance or smart manufacturing solutions, reach out to BOSC Tech Labs, and we can help you get there. We develop custom manufacturing software tailored to your operations, solves real problems, and keeps your manufacturing moving. We four will help you make smarter decisions using your data—contact us today!